Inconel Stamping Excellence

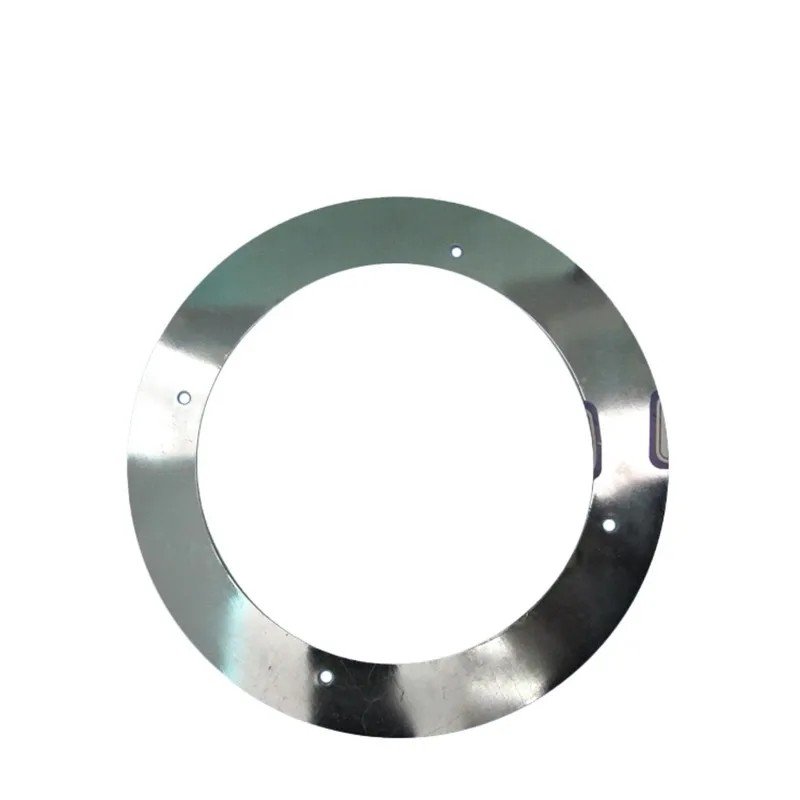

Rapidaccu specializes in precision Inconel stamping for the most demanding high-temperature and corrosive environments. Our expertise in working with these challenging nickel-based superalloys ensures superior performance for aerospace, chemical processing, and extreme-condition applications.

What is Inconel?

Inconel is a family of nickel-chromium-based superalloys known for their exceptional performance in extreme conditions. These materials maintain their strength and resist oxidation and corrosion even at temperatures exceeding 1000°C, making them essential for aerospace, chemical processing, and high-temperature industrial applications.

Extreme Temperature Resistance

Maintains mechanical strength and structural integrity at temperatures up to 1200°C, far exceeding standard alloys.

Superior Corrosion Resistance

Exceptional resistance to oxidation, carburization, and corrosive chemicals in harsh environments.

High Strength Properties

Outstanding tensile and creep-rupture strength, even under extreme stress and temperature conditions.

Our Inconel Stamping Expertise

Technical Capabilities

Inconel Grades

We specialize in stamping various Inconel grades based on your application requirements:

Progressive Die Stamping

Multi-stage forming for complex geometries

Deep Drawing

Complex three-dimensional shapes

Fine Blanking

High-precision edge quality

Inconel Stamping Applications

Aerospace Components

High-Temp Applications

Custom Components

Critical Industry Applications

Aerospace

- • Turbine blades

- • Exhaust systems

- • Thrust reversers

- • Rocket components

Chemical Processing

- • Reaction vessels

- • Heat exchangers

- • Valve components

- • Pump parts

Oil & Gas

- • Downhole equipment

- • Wellhead components

- • Pressure vessels

- • Piping systems

Power Generation

- • Gas turbines

- • Nuclear reactors

- • Boiler components

- • Heat shields

Why Choose Rapidaccu for Inconel Stamping?

Working with Inconel requires specialized expertise, advanced equipment, and rigorous quality control. Rapidaccu brings all three to deliver exceptional results for the most demanding applications.

Years of Expertise

Specialized experience in difficult-to-machine superalloys and high-temperature materials

Specialized Equipment

High-tonnage presses and advanced tooling designed for superalloy forming

Quality Certified

ISO-certified with aerospace-grade quality control and material traceability

Proven Reliability

Trusted by aerospace and industrial clients for critical applications

Inconel Stamping FAQs

Why is Inconel difficult to stamp?

What Inconel grades can you stamp?

What precision can you achieve with Inconel?

Can you provide material certifications?

What secondary processes are available?

How do I get a quote for Inconel stamping?

Start Your Inconel Stamping Project

Partner with Rapidaccu for your high-performance Inconel components

Get In Touch

Manufacturing Location

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Address

info@rapidaccu.comOperating Hours

Monday – Friday: 8:00 AM – 6:00 PM

Saturday: 9:00 AM – 5:00 PM

(China Standard Time)