Elite Surface Finishing

Mastery & Precision

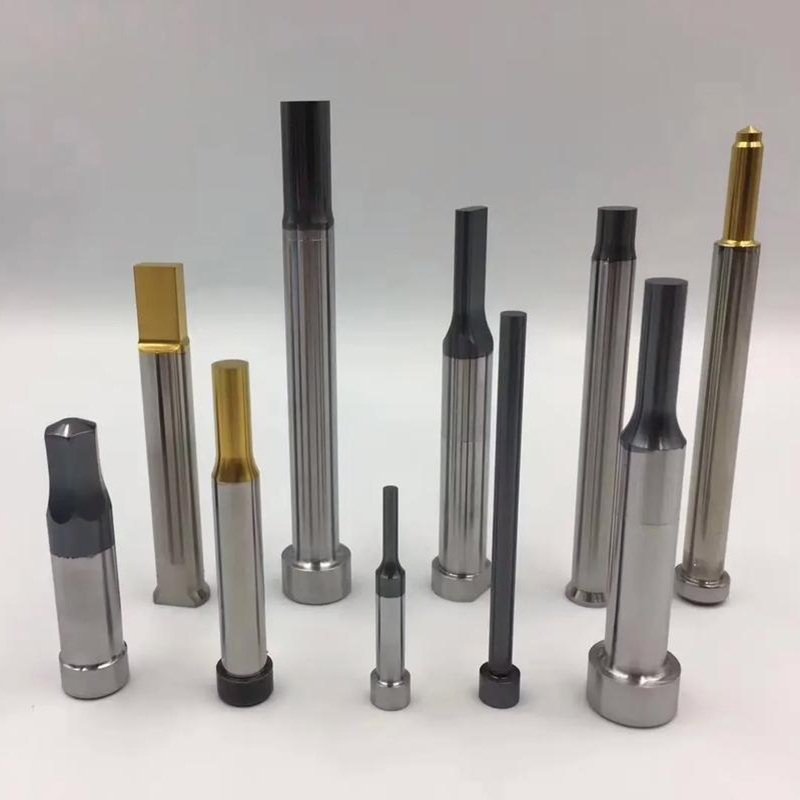

Elevate your manufacturing quality with our high-end surface treatment solutions. From aerospace-grade anodizing to luxury PVD coatings, we ensure your parts exceed expectations.

The Finishing Touch of Engineering

Functional Integrity

Enhancing hardness, wear resistance, and conductivity for critical components.

Visual Perfection

Achieving precise colors, gloss levels, and textures for consumer market success.

Eco-Compliance

Our processes meet strict RoHS and REACH standards for environmental safety.

Surface Finishing Comparison

Hover over preview images to see larger detail.

| Preview | Finishing Type | Process Description | Key Benefits | Typical Materials | Common Applications | Popularity |

|---|---|---|---|---|---|---|

|

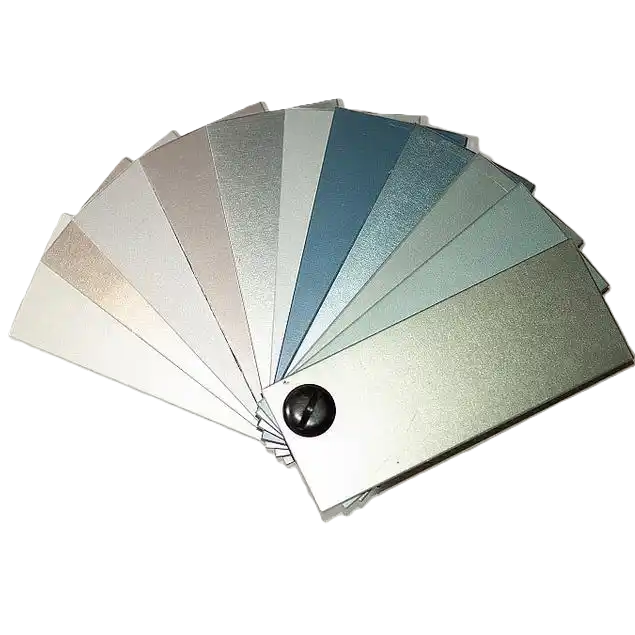

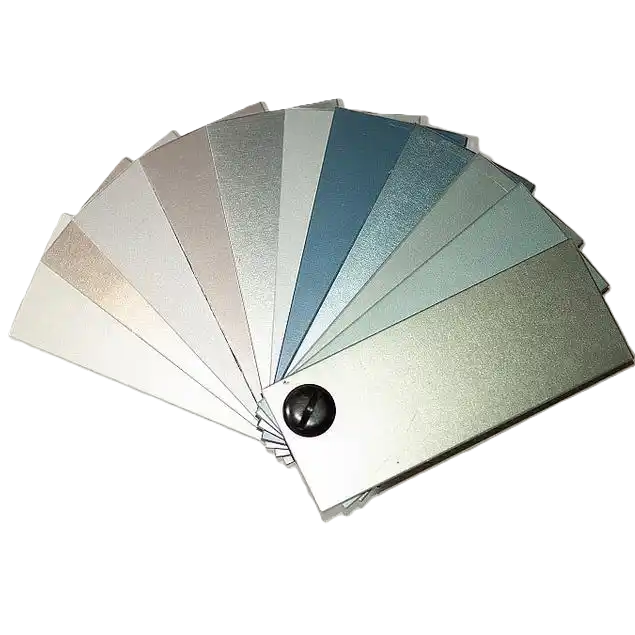

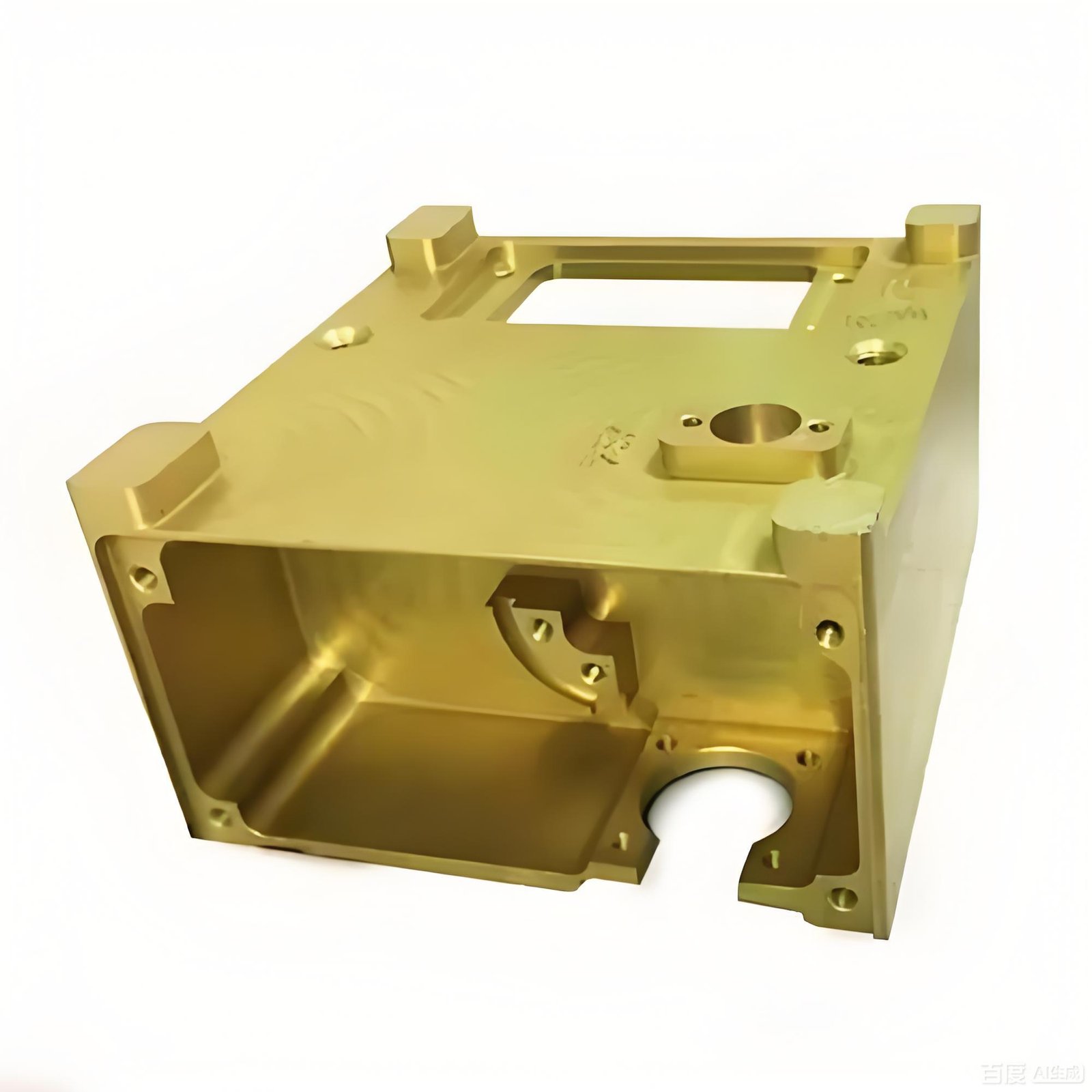

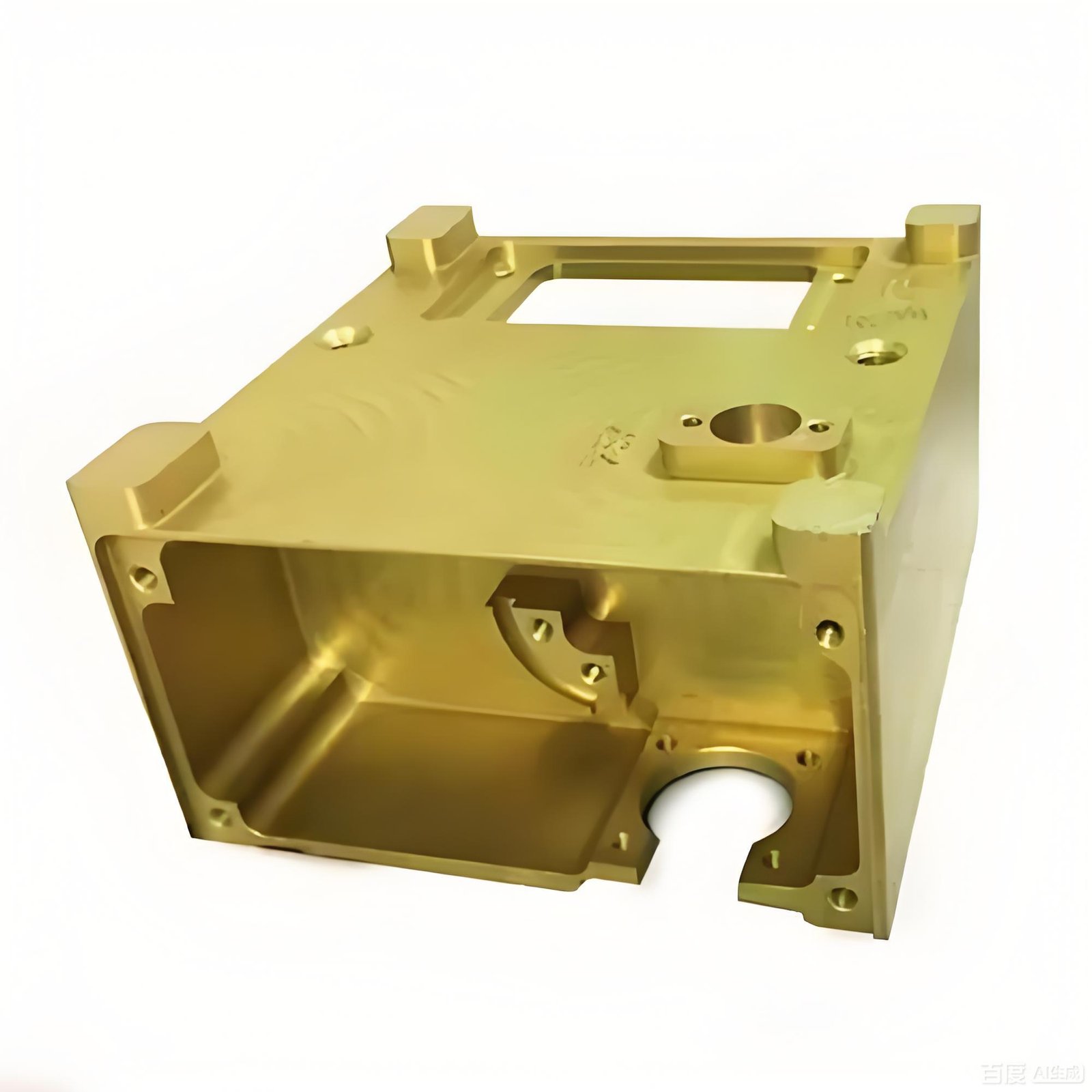

Anodized | Electrochemical process to convert metal surface into durable oxide layer. | Corrosion resistant, hard, colorful. | Aluminum, Titanium, Magnesium. | Aerospace, Smartphone bodies, Kitchenware. | ★★★★★ |

|

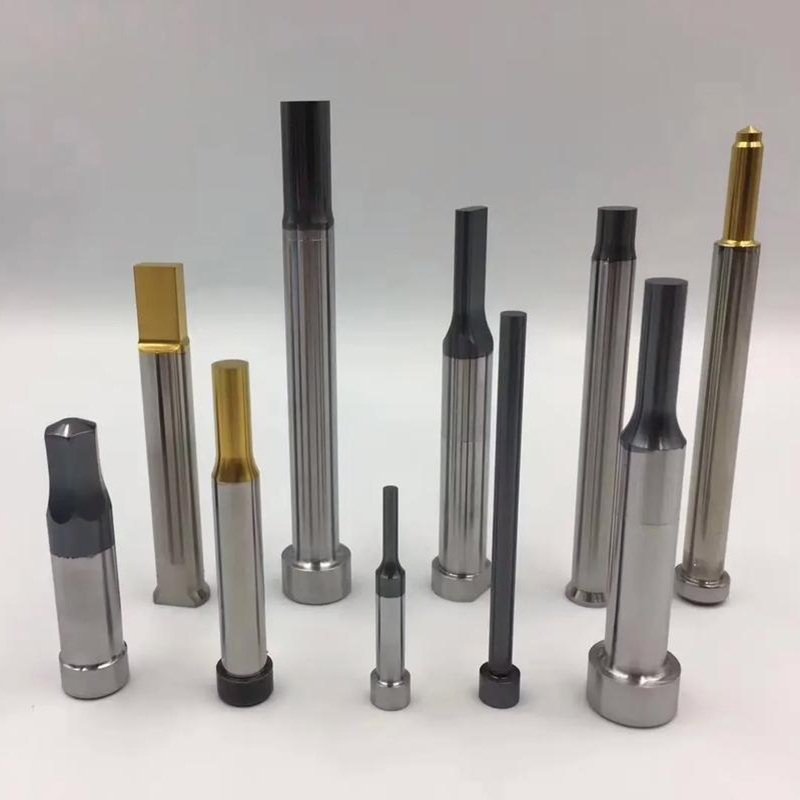

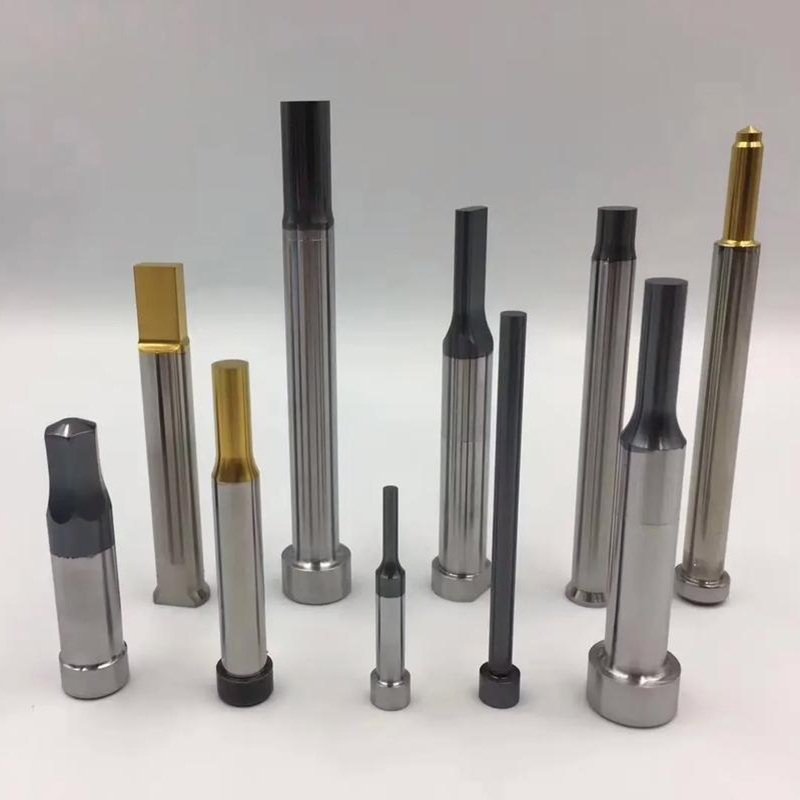

PVD Coating | Vaporization of material in vacuum to form a thin film coating. | Extreme hardness, wear resistance, luxury look. | Stainless Steel, Alloys, Brass. | Luxury watches, Jewelry, Cutting tools. | ★★★★★ |

|

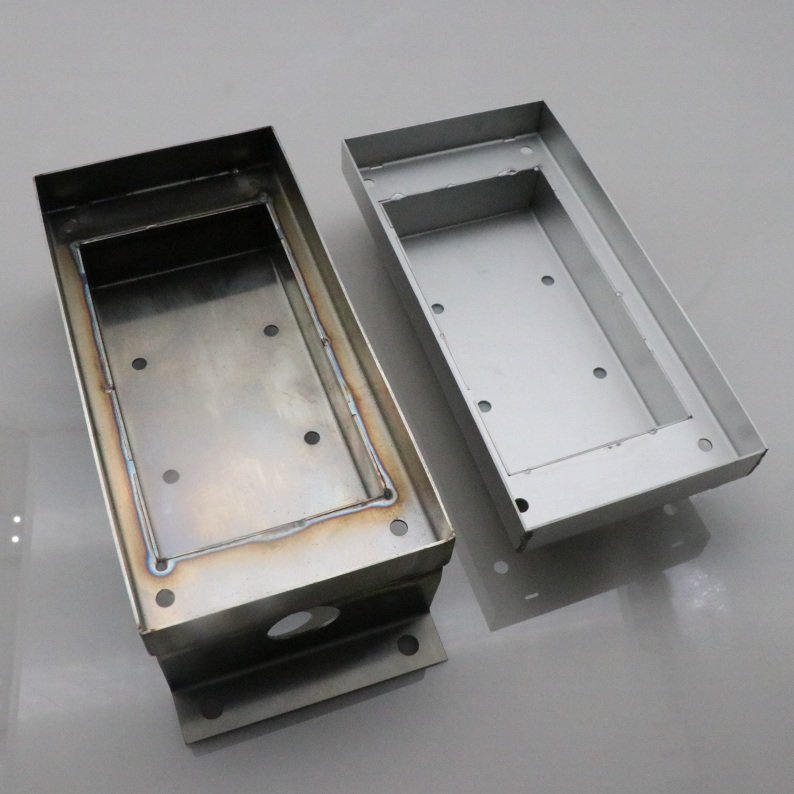

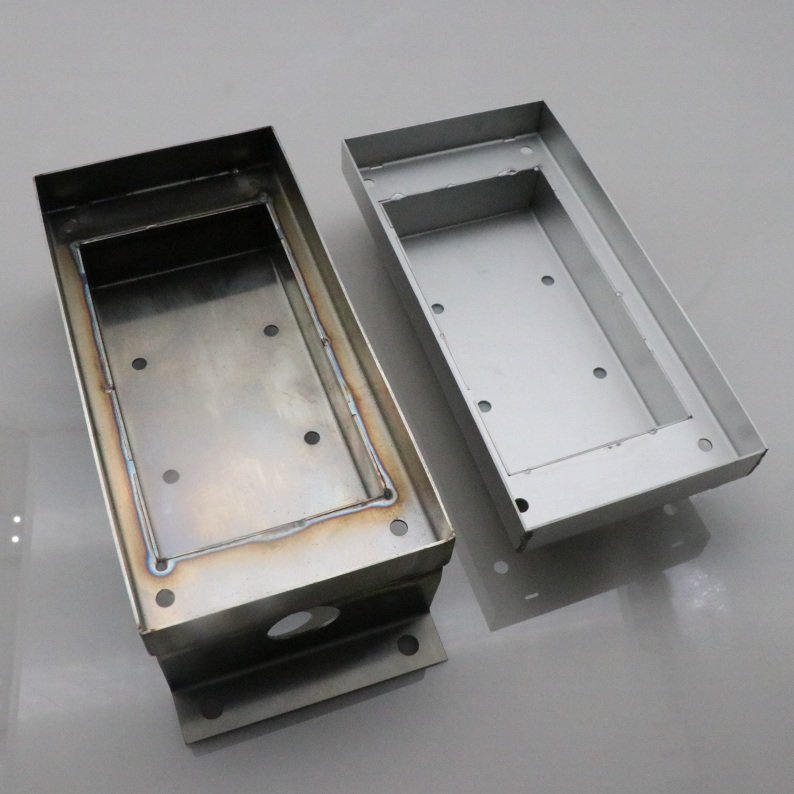

Powder Coat | Dry powder applied electrostatically and cured under heat. | Impact resistant, thick layer, vast colors. | Steel, Aluminum, Cast Iron. | Auto parts, Outdoor furniture, Enclosures. | ★★★★★ |

|

Bead Blast | Blasting glass beads at high pressure against a surface. | Uniform matte finish, hides tool marks. | All metals & plastics. | Camera bodies, Medical devices, Industrial equipment. | ★★★★☆ |

|

Brushed | Mechanical polishing with abrasive belts to create linear patterns. | High-end texture, hides scratches. | Stainless Steel, Aluminum. | Home appliances, Architecture, Decorative trim. | ★★★★☆ |

|

Chrome Plating | Electroplating a thin layer of chromium onto a metal object. | Mirror shine, low friction, corrosion resistance. | Steel, Zinc alloys, Copper. | Automotive wheels, Plumbings, Hydraulics. | ★★★★☆ |

|

Passivation | Chemical treatment to remove free iron and enhance oxide layer. | Superior rust prevention, biocompatibility. | Stainless Steel. | Medical instruments, Food equipment, Semiconductors. | ★★★★☆ |

|

Nickel Plating | Electroless or electrolytic deposition of nickel. | Hardness, lubricity, anti-corrosion. | Steel, Copper, Aluminum. | Electronics housings, Fasteners, Gears. | ★★★☆☆ |

|

Zinc Plating | Applying a protective zinc coating to steel or iron. | Cost-effective rust protection (Sacrificial layer). | Iron, Steel. | Bolts, Nuts, Construction brackets. | ★★★☆☆ |

|

Black Oxide | Chemical conversion coating used to change surface color to black. | Low light reflection, minimal dimension change. | Steel, Stainless Steel, Copper. | Firearms, Precision tools, Optical parts. | ★★★☆☆ |

|

Gold Plating | Depositing a thin layer of gold onto the surface of another metal. | Excellent conductivity, oxidation-free, luxury finish. | Copper, Silver, Nickel. | PCB contacts, High-end audio jacks, Jewelry. | ★★★☆☆ |

|

Silver Plating | Electrochemical process of applying a layer of silver. | Highest electrical conductivity, thermal performance. | Copper, Brass, Nickel. | RF components, Power connectors, Solar cells. | ★★★☆☆ |

|

Laser Engraving | High-power laser beams to etch or mark materials. | Permanent, high precision, versatile. | All metals, most plastics. | Serialization, Logos, Custom branding. | ★★☆☆☆ |

|

Silkscreen | Pressing ink through a stenciled mesh screen onto the part. | Vibrant colors, cost-effective for batches. | Metals, Plastics, Glass. | Control panels, Enclosures, Signage. | ★★☆☆☆ |

|

Electropolished | Electrochemical removal of material to smooth out micro-peaks. | Ultra-clean, burr-free, sanitary. | Stainless Steel, Alloys. | Medical implants, Biotech pipes, Vacuum chambers. | ★★☆☆☆ |

|

Spray Painting | Atomizing paint into a fine mist and spraying onto parts. | Limitless color range, matte/gloss options. | Plastics, Wood, Metal. | Consumer gadgets, Interior car parts, Prototypes. | ★★☆☆☆ |

|

Electrophoresis | Submerging parts in a liquid bath with electrical charge to attract paint. | Uniform thickness, 100% coverage on complex shapes. | Iron, Steel, Alloys. | Automotive chassis, Hardware parts. | ★★☆☆☆ |

|

Tin Plating | Applying a layer of tin for high solderability. | Good solderability, corrosion resistance. | Copper, Brass, Steel. | Electrical connectors, Busbars. | ★★☆☆☆ |

|

Chem-Film | Chromate conversion coating to protect aluminum. | Maintains conductivity, excellent paint base. | Aluminum. | Military housings, Aircraft components. | ★☆☆☆☆ |

|

Conductive Oxidation | Specific oxidation that allows electric flow while protecting surface. | EMI shielding, rust prevention. | Aluminum alloys. | Server racks, Electronics shielding. | ★☆☆☆☆ |

|

Etching | Using acids to dissolve material and create designs or textures. | High precision patterns, permanent. | Glass, Metals, PCB. | Decorative glass, Serial numbers, Micro-fluidics. | ★☆☆☆☆ |

|

Vacuum Plating | Evaporating metal onto parts within a vacuum chamber. | Metallic look on plastic, cost-effective. | ABS, Polycarbonate, Zinc. | Cosmetic containers, Plastic toys. | ★☆☆☆☆ |

|

Pickling | Chemical removal of surface impurities or scale using “pickle liquor”. | Removes oxidation, prepares for coating. | Iron, Steel, Copper. | Pre-plating prep, Descaling industrial pipes. | ★☆☆☆☆ |

Industry Leading Capabilities

Aerospace

Precision anodizing and chemical film for extreme environmental endurance.

Medical

Electropolishing and passivation for 100% sterile and smooth surgical tools.

Electronics

Gold and Silver plating to ensure zero-loss electrical signal transmission.

Automotive

Heavy-duty powder coating and chrome plating for aesthetics and road durability.

Unmatched Visual Quality

“We don’t just coat parts; we engineer their final identity.”

From the first prototype to mass production, our quality control team uses micron-precision tools to measure thickness and adhesion, ensuring every part is flawless.

Get an Instant QuoteChoosing the Right Finish?

Our engineers are ready to help you select the most cost-effective finishing based on your material and functional requirements.

Surface Finishing FAQ

Which finish provides the best hardness for aluminum?

Can PVD be applied to any material?

Does surface finishing affect part tolerances?

RapidAccu

Ready to start? Upload your design files for a comprehensive analysis of finishing costs and lead times.

- info@rapidaccu.com

- Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China