More than 75% of common consumer housings and automotive trim use a thermoplastic that softens near 200°C, making control of melt crucial for consistent parts.

This guide defines whats is the abs melting point and why that range drives manufacturability. You will learn how temperature affects flow, surface finish, and dimensional stability during molding and 3D printing.

ABS plastic offers toughness, impact resistance, and good machinability. Typical processing temperatures sit around 220–260°C, while glass transition occurs near 105°C and Vicat softening falls close to 90–110°C.

Rapidaccu brings over 15 years of CNC machining and manufacturing expertise to help turn prototypes into production. We pair material knowledge with tight process control to protect quality and operator safety.

ABS Fundamentals: Acrylonitrile Butadiene Styrene and Why Melting Point Matters

Acrylonitrile butadiene styrene blends combine three monomers to deliver a compact set of traits: toughness, rigidity, and surface finish useful for consumer housings and automotive trim.

At the chemistry level, styrene provides rigidity and glossy surfaces. Acrylonitrile increases chemical resistance and heat stability. Butadiene supplies impact strength and energy absorption during shocks.

ABS exhibits a mix of amorphous and modestly crystalline regions. That morphology yields strength, ease of machining, and reliable performance under typical manufacturing temperatures. Glass transition near 105°C marks when chains gain mobility and parts begin to soften during forming or service.

- Produced by graft copolymerization or by blending SAN with polybutadiene to tune flow and toughness.

- Common in dashboards, enclosures, and snap-fits that need durable surfaces and repeatable tolerances.

- Rapidaccu advises engineers on grade selection and machining settings to protect critical finishes and dimensions.

| Monomer | Primary Role | Effect on Properties |

|---|---|---|

| Acrylonitrile | Chemical resistance | Improves solvent resistance and dimensional stability |

| Butadiene | Impact modifier | Boosts toughness and shock absorption |

| Styrene | Rigid matrix | Delivers surface quality and stiffness for machining |

whats is the abs melting point: the quick answer

Understanding when a polymer starts to flow gives engineers a practical window for molding and printing. Rapidaccu offers quick design-for-manufacturing feedback so teams can match processing targets to downstream machining and finishing steps.

Typical melting range in °C/°F and what “melting” means

ABS generally begins to melt near 200°C (392°F) and reaches full flow around 240°C (464°F). Most shops run 220–260°C to balance viscosity and fill without pushing degradation.

- Start of melt: ~200°C; full flow by ~240°C.

- Processing window: 220–260°C for reliable fill and surface finish.

- Degradation risk rises above ~270°C; avoid excess residence time.

| Phase | Typical °C | Why it matters |

|---|---|---|

| Onset of flow | ~200 | Enables initial cavity filling |

| Optimal flow | 220–260 | Balances viscosity and finish |

| Degradation | >270 | Color, strength, and odor loss |

For practical guidance and grade-specific ranges, see our detailed ABS plastic temperature guide: ABS plastic temperature guide.

Melting vs Softening vs Glass Transition

Different temperature landmarks in polymers govern how parts hold shape and resist deformation.

Glass transition and Vicat softening

Glass transition (Tg) sits near 105°C and marks when material changes from rigid to rubbery. This shift reduces stiffness and alters dimensional control under service heat.

Vicat softening often appears around 90–110°C and flags early loss of rigidity, even though true melting is far higher.

Why dashboards mold at high temps but can warp in sun

Dashboards are molded near 230°C to get flow and detail; full melt enables fine features. Yet parked cars can reach 80–90°C at the surface, close to Vicat levels, causing slight warpage if design lacks reinforcement.

- Designers use ribs, tuned wall thickness, and reinforcements to protect dimensional stability.

- Grade selection and additives preserve key properties near Tg for interior parts.

- Rapidaccu advises tolerances and post-processing to avoid fits that bind as parts pass through service thresholds.

| Transition | Typical °C | Impact |

|---|---|---|

| Vicat softening | 90–110 | Loss of rigidity |

| Glass transition | ~105 | Rubbery behavior, reduced stiffness |

| Melting onset | ~200+ | Flow for molding |

ABS Melting Point Ranges and Processing Windows

Control of processing temperatures defines part quality and safety during molding and later machining. Establishing a reliable window reduces variability and helps teams plan downstream CNC sequences to preserve edges, holes, and critical surfaces.

Onset and optimal ranges

Most grades begin to melt near 200°C and reach efficient flow between 220–260°C. Running within that band gives consistent viscosity, good surface finish, and strong knit lines across cavities.

Degradation risks and safety controls

Temperatures above about 270°C accelerate degradation, which can yellow parts, weaken welds, and release styrene fumes. Processors limit residence time, control shear, and use ventilation or nitrogen blanketing to reduce oxidation and fumes.

- Mold setpoints of 50–80°C improve gloss and prevent thin-section freeze-off.

- Gate and runner design reduce excessive shear and keep apparent viscosity predictable.

- Downstream machining should avoid reheating surfaces; coolant choice helps maintain thermal stability.

| Phase | Typical °C | Key control |

|---|---|---|

| Onset of flow | ~200 | Start melt monitoring |

| Optimal processing | 220–260 | Stable barrel profile |

| Degradation | >270 | Reduce residence, venting |

What Influences ABS Melting Behavior

Molecular architecture and additives determine flow, stiffness, and thermal response during manufacture.

Grades vary by chain length and monomer mix, so processing targets shift with composition. Rapidaccu helps compare formulations to match machining behavior and finish without hurting mechanical performance.

Molecular weight and monomer ratios

Higher molecular weight raises viscosity and often requires higher temperatures for similar fill. That trend affects cycle time and tool wear during machining.

Changing acrylonitrile, butadiene, and styrene ratios tunes toughness, chemical resistance, and rigidity. Different monomers yield varied characteristics and in-service resistance and strength.

Additives and reinforcements

Glass fiber raises stiffness and can increase effective processing temperatures by about 15°C while reducing flow. It also increases abrasive wear on cutters.

Stabilizers, UV absorbers, antioxidants, and impact modifiers protect parts from photooxidation and brittle failure, extending service life.

Heating rate, shear, and processing effects

Fast temperature ramps or high shear produce local hot spots that risk thermal degradation or discoloration. Slow ramps and balanced screw profiles promote uniform melt and predictable flow.

Gate design and controlled residence time let processors lower apparent viscosity through shear while preventing damage to the polymer matrix.

- Molecular weight controls melt viscosity and filling behavior.

- Monomer ratios adjust toughness, resistance, and rigidity.

- Glass fiber and fillers raise stiffness but cut flow and increase wear.

- Stabilizers preserve properties over longer lifecycles.

| Factor | Typical Effect | Manufacturing Impact |

|---|---|---|

| Molecular weight | Higher viscosity | Need higher barrel temps; longer cycle times |

| Monomer ratio | Tune toughness and resistance | Alters target temps and in-service performance |

| Glass fiber | +15°C apparent melt, increased stiffness | Reduced flow; more tool wear during machining |

| Heating/shear | Hot spots or reduced viscosity | Manage ramps and screw profile to avoid degradation |

From Injection Molding to 3D Printing: Practical Temperature Guidelines

Bridging molded blanks and printed parts to CNC finishing starts with repeatable temperature practice. This short guide gives clear setpoints and handling tips that protect features, hole positions, and surface quality as parts move to Rapidaccu for final machining.

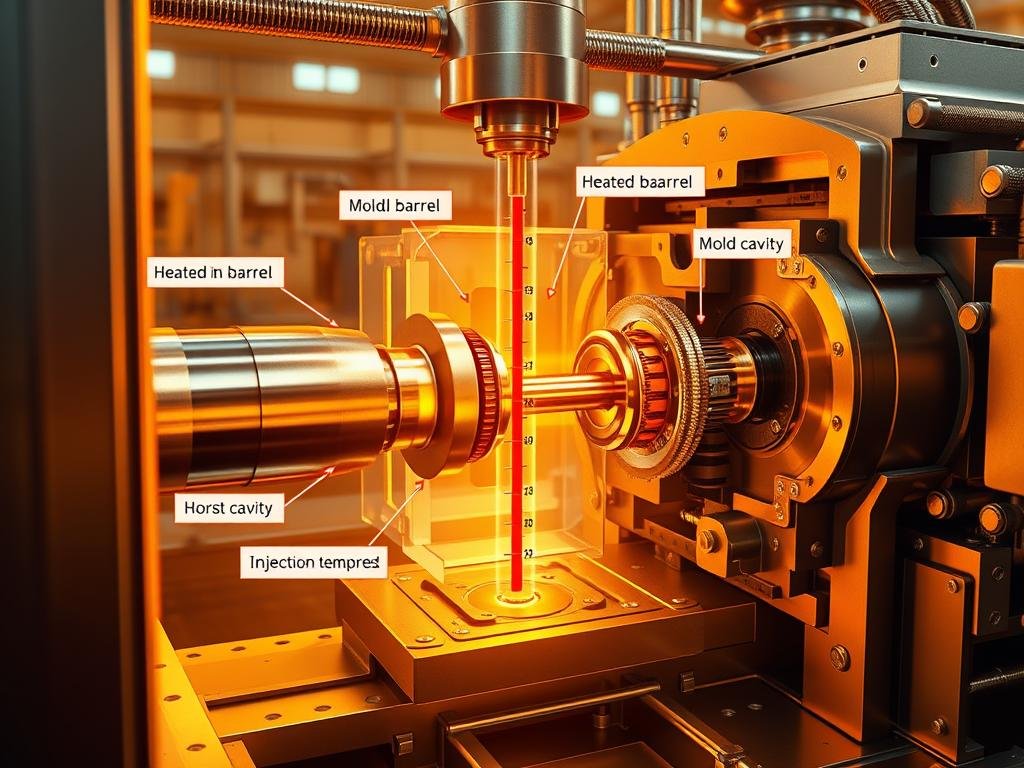

Injection molding: barrel zones, mold temperature, cycle efficiency

Stage barrel zones from about 210°C at the rear to 230°C at the front to avoid thermal shock and keep melt viscosity steady. Maintain mold temperatures near 50–80°C to improve flow into thin features and boost gloss.

Cooling estimates of roughly 3 seconds per mm wall thickness balance cycle time and residual stress. Monitor residence time and back pressure to prevent discoloration or brittle welds.

| Setting | Typical | Purpose |

|---|---|---|

| Barrel zones | 210→230°C | Stable melt, less shear |

| Mold temp | 50–80°C | Gloss, thin-section fill |

| Cooling | ~3 s/mm | Minimize stress, speed cycles |

3D printing: nozzle/bed, chamber control, warp prevention

For FDM, use a hotter first layer — about 260°C nozzle with a 110°C bed — then drop to ~240°C for steady printing of abs plastic. Keep an enclosure at 50°C or higher to reduce thermal gradients and curling.

Use bed adhesives and low fan speeds during early layers to improve interlayer bonding. Above ~270°C, degradation and fumes increase; ensure ventilation and purge routines are in place.

- Coordinate blanks with Rapidaccu so datum faces and critical components arrive with enough stock for machining.

- Follow these manufacturing processes to preserve tolerances and overall quality.

- For deeper guidance on temperature ranges, see this industry note: ABS temperature overview.

How ABS Compares: Plastics and Metals in Heat and Performance

For many consumer and automotive uses, material trade-offs determine whether plastic or metal suits a job. Rapidaccu advises engineers on those trade-offs so parts meet cost, weight, and service needs.

ABS versus common polymers and metals

ABS melts around 200–240°C, while PP and HDPE soften at lower temperatures. That gives better heat resistance and dimensional control in warm service.

Near 60°C, ABS holds strength that PLA often loses. This makes ABS preferable for warm environments and many consumer applications.

- High impact resistance and machinability suit housings, vents, and brackets.

- Metals outperform for continuous service at high temperatures or heavy loads.

- ABS wins on weight, cost, and design freedom for interiors and electronics shells.

| Material | Heat resistance | Impact resistance | Common applications |

|---|---|---|---|

| ABS | ~200–240°C melt range; good to ~100°C service | High | Housings, trim, enclosures |

| PP/HDPE | Lower melt; less dimensional control at elevated service temps | Moderate | Containers, simple covers |

| PLA | Softens near 60°C; poor for warm service | Low–moderate | Prototypes, nonheated parts |

| Metals | Stable at high temperatures and loads | Very high | Structural, engine mounts, heat-critical parts |

Rapidaccu helps teams pick between polymers and metals by matching heat exposure, tolerance needs, and lifecycle goals.

Real-World Applications Enabled by ABS Thermal Properties

Manufacturers choose polymer grades that balance heat response and toughness for parts exposed to changing temperatures. That choice drives which applications and components perform reliably in service.

Automotive components and cabin heat

Dashboards and vents are molded near 230°C but can see 80–90°C on sunny days. Designers add ribs, reinforced bosses, or fiber to avoid minor warpage during summer cycles.

Electronics and industrial uses

For housings, jigs, and CNC fixtures, dimensional stability matters. Stabilizers and glass fiber reinforce mounting points and high-heat zones without adding metal weight.

- Automotive interior components like bezels combine crisp detail with resistance to cabin heat cycles.

- Electronics frames and handheld shells use stiffness plus impact absorption for daily use.

- Industrial jigs and guides offer strength for fixturing while saving on cost and mass.

| Application | Key trait | Manufacturing note |

|---|---|---|

| Dashboard panels | Heat resistance | Reinforce thin sections |

| Handheld housings | Impact absorption | Control gate and cooling |

| Jigs/fixtures | Dimensional stability | CNC finish to datums |

Rapidaccu machines resin and metals into production-grade parts that keep surface finish and tolerances for drop-in assembly. Across various applications, this material offers a trusted mix of resistance and strength when designs respect glass transition and softening behavior.

Rapidaccu’s Role: Precision CNC Machining for ABS and Metals

Rapidaccu pairs machining know-how with material science to turn designs into production-grade parts. With over 15 years of CNC machining and manufacturing expertise, we deliver precision work for both plastics and metals.

Prototype-to-production quality: tolerances, surface finish, and repeatability

We produce repeatable tolerances and production-grade surface finish for tight assemblies and critical components. Our process control reduces variation so parts fit without extra rework.

For heat-sensitive material, we plan feeds and cutting parameters to avoid stress, chatter, or thermal damage during finishing. Reinforced grades get adjusted toolpaths and cutters to handle abrasive fillers while keeping finish standards.

Selecting the right process: when to machine versus molding

For fast-turn prototypes, fixtures, and low-to-mid volumes, CNC machining gives speed and flexibility. Injection molding becomes more economical as volume grows and when parts need complex thin features at low per-piece cost.

- We advise on manufacturing processes to match volume, lead time, and end-use requirements.

- Design guidance considers glass transition and degradation thresholds so components hold dimensional stability in service.

- We collaborate on datum and stock strategies so molded blanks arrive ready for precise secondary machining.

| Service need | Suggested process | Key benefit |

|---|---|---|

| Rapid validation | Machining | Fast turn, low tooling cost |

| High volume | Molding | Lower unit cost |

| Reinforced grades | Machining with adjusted tooling | Controlled wear, consistent finish |

Conclusion

A concise thermal strategy bridges design, molding, printing, and final machining for repeatable outcomes.

Master key numbers: melting point around 200–240°C, processing near 220–260°C, glass transition ~105°C, Vicat ~90–110°C, with degradation risks above 270°C. These temperatures guide material choices and process control for consistent properties and impact resistance in various applications.

Respecting these limits preserves color, strength, and odor while avoiding scrap. Use injection molding for high volumes and CNC machining for fast turn prototypes and precision finishes.

Rapidaccu stands ready to convert thermal insight into finished components. With over 15 years of CNC expertise, Rapidaccu delivers parts in plastics and metals from prototype through production with repeatable quality and controlled manufacturing processes.