- Home ›

- Metal Machining ›

- Brass Machining

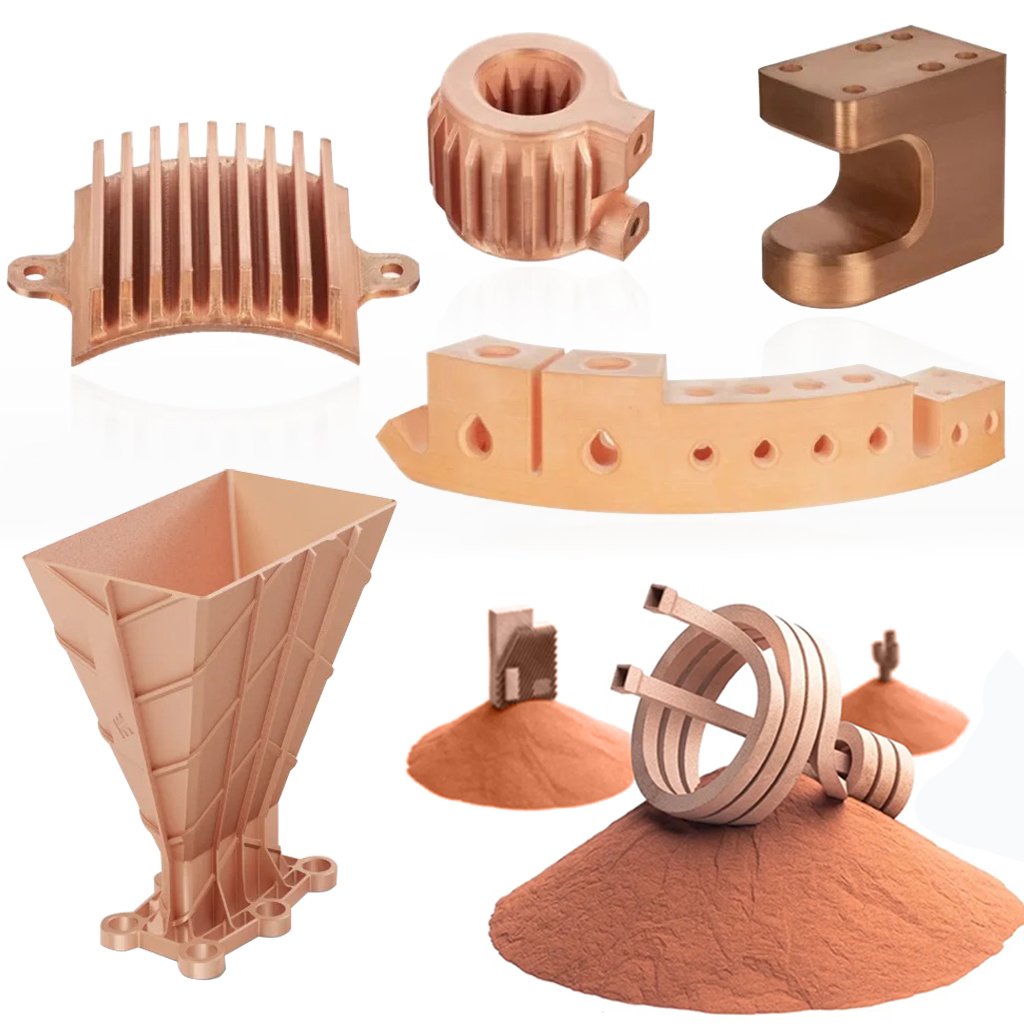

Professional Brass Machining Services

Precision brass parts manufacturing with 15 years of industry expertise

- Expert CNC machining for intricate brass components with superior dimensional accuracy

- Comprehensive brass processing including stamping, 3D printing and sheet metal fabrication

- Wide range of brass alloys for optimal performance in your application

- Strict quality standards ensuring consistent excellence in every brass part

Brass Manufacturing Technologies

Rapidaccu offers a complete range of brass processing capabilities to meet your precision manufacturing needs

CNC Machining Brass Parts

High-precision milling and turning for complex brass components

Brass Stamping

Efficient high-volume production of brass stamped parts

Brass 3D Printing

Additive manufacturing for complex brass geometries

Brass Sheet Metal Fabrication

Custom cutting, bending and forming brass sheet metal

Superior Brass Machining Capabilities

As a leading brass parts manufacturer in China, Rapidaccu combines advanced technology with skilled craftsmanship to deliver exceptional brass components for global clients. Our facility in Shenzhen is equipped with state-of-the-art CNC machines and staffed by experienced engineers.

Brass offers excellent machinability, corrosion resistance, and aesthetic appeal, making it ideal for components in plumbing, electrical, automotive, and decorative applications.

Multiple Alloys

C260, C360, C464, and more

Quality Certified

ISO 9001:2015 compliant

Global Shipping

Worldwide delivery available

Expert Support

Engineering consultation

Why Choose Rapidaccu?

-

Precision Manufacturing

Tolerances down to ±0.005mm for critical brass components

-

Flexible Production

From single prototypes to large production volumes

-

Surface Finishing

Polishing, plating, and coating options available

-

Competitive Pricing

Cost-effective solutions without compromising quality

Our Brass Machining Workflow

A streamlined process ensures your brass parts are manufactured to exact specifications

Quote & Design Review

Submit your drawings for a detailed quote and design for manufacturability analysis

Material Procurement

Select from premium brass alloys suited to your application requirements

CNC Programming & Setup

Expert programmers optimize toolpaths for efficient brass machining

Production & Finishing

Precision machining followed by selected surface treatments and finishes

Quality Control & Delivery

Comprehensive inspection and secure packaging for international shipping

Trusted Brass Machining Partner

With 15 years of experience serving international clients, Rapidaccu has earned a reputation for delivering high-quality brass components on time and within budget.

Our commitment to excellence is reflected in our rigorous quality control processes, investment in advanced equipment, and dedication to customer satisfaction.

“We don’t just manufacture brass parts – we build lasting partnerships with our clients by delivering exceptional value and reliability in every project.”

Industries We Serve

Electrical

Plumbing

Automotive

Musical

Marine

Hardware

Common Brass Alloys We Machine

Each brass alloy offers unique properties for specific applications

C260 Brass

Cartridge brass with excellent cold working properties for deep drawing and forming

C360 Brass

Free-cutting brass offering superior machinability for complex components

C464 Brass

Naval brass with excellent corrosion resistance in marine environments

C280 Brass

Muntz metal ideal for architectural and structural applications

Frequently Asked Questions About Brass Machining

What brass machining services does Rapidaccu provide?

What are the advantages of brass for machined parts?

Which brass alloys can you machine?

What tolerances can you achieve for brass parts?

Do you offer surface finishes for brass components?

What is the lead time for brass machining projects?

Request Your Brass Machining Quote

Connect with Rapidaccu to discuss your brass machining requirements. Our experienced team is ready to provide expert guidance and competitive pricing.

Manufacturing Facility

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Address

info@rapidaccu.comWorking Hours

Monday – Friday: 9:00 AM – 6:00 PM (China Standard Time)