- Home ›

- Metal Machining ›

- Cast Iron Machining

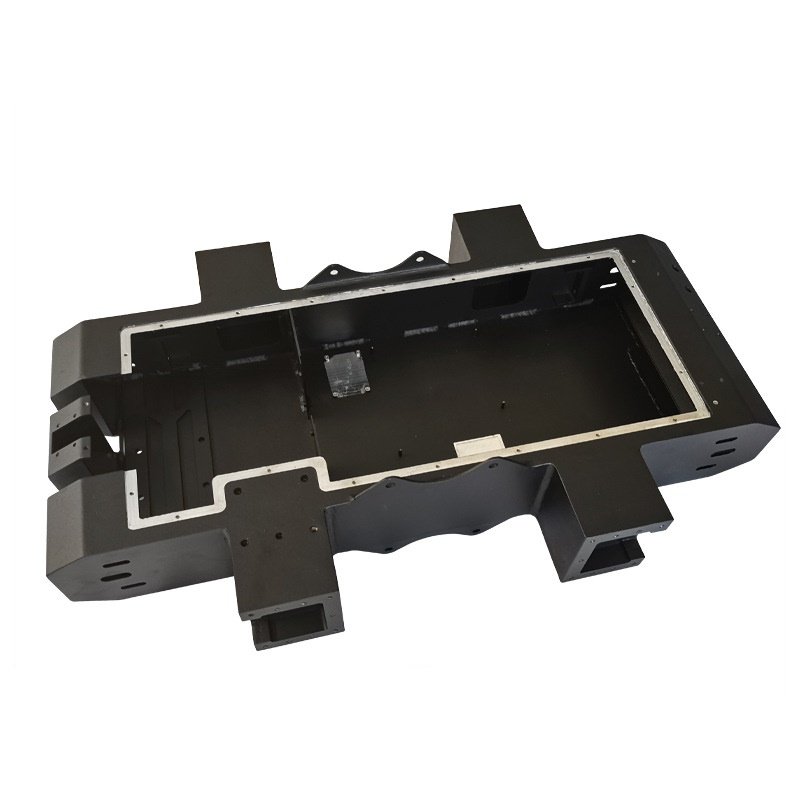

Cast Iron Machining Services

Expert cast iron parts manufacturing with 15 years of proven experience

- Excellent vibration damping and thermal conductivity for machine components

- Advanced CNC machining for complex cast iron parts with superior dimensional accuracy

- Comprehensive cast iron processing including sheet metal fabrication and stamping

- Cost-effective material choice with excellent machinability and wear resistance

Cast Iron Manufacturing Services

Rapidaccu delivers precision cast iron machining solutions with advanced equipment and extensive material expertise

Types of Cast Iron We Machine

Gray Cast Iron

Most widely used cast iron with excellent machinability, damping capacity, and wear resistance. The graphite flakes give it a gray appearance.

Applications:

Engine blocks, machine tool bases, brake discs, flywheels

Properties:

Good machinability, excellent damping, thermal conductivity

Ductile Iron

Also known as nodular cast iron, features spheroidal graphite structure providing higher strength, ductility and impact resistance than gray iron.

Applications:

Crankshafts, gears, suspension components, pipe fittings

Properties:

High tensile strength, good ductility, impact resistance

White Cast Iron

Contains carbides in its structure, making it extremely hard and wear-resistant but difficult to machine. Often used in abrasive environments.

Applications:

Mill liners, crushing equipment, wear plates, shot blasting

Properties:

Extreme hardness, high wear resistance, brittle

Malleable Cast Iron

White cast iron heat-treated to break down carbides, resulting in improved ductility and shock resistance while maintaining good strength.

Applications:

Pipe fittings, brackets, hand tools, agricultural equipment

Properties:

Good ductility, machinability, shock resistance

Advantages of Cast Iron for Manufacturing

Cast iron offers a unique combination of properties that make it an excellent choice for numerous industrial applications. Understanding these advantages helps optimize component design and material selection.

Cost-Effective Solution

Lower material costs compared to steel and superior castability allow for complex shapes to be produced economically, reducing overall manufacturing expenses.

Vibration Damping

Excellent vibration damping capacity makes cast iron ideal for machine tool bases, engine blocks, and equipment requiring stability and reduced noise transmission.

Superior Machinability

Gray cast iron offers excellent machinability, allowing for efficient production with reduced tool wear, lower cutting forces, and improved surface finish quality.

Wear Resistance

The graphite structure provides self-lubricating properties and excellent wear resistance, extending component life in friction and sliding applications.

Material Comparison

Industries Relying on Cast Iron Components

Automotive

Engine blocks, cylinder heads, brake discs, flywheels, and transmission housings requiring vibration damping.

- • Engine components

- • Brake systems

- • Drivetrain parts

Machine Tools

Machine tool bases, beds, and structural components where vibration damping and stability are critical.

- • Lathe beds

- • Milling machine bases

- • Press frames

Plumbing & Piping

Pipe fittings, valves, pumps, and water distribution systems requiring corrosion resistance and durability.

- • Pipe fittings

- • Valve bodies

- • Pump housings

Heavy Machinery

Construction and mining equipment, agricultural machinery, and industrial equipment requiring strength and wear resistance.

- • Excavator components

- • Agricultural equipment

- • Mining machinery

Power Generation

Turbine housings, generator components, and power transmission parts for electrical power generation systems.

- • Turbine housings

- • Generator frames

- • Bearing supports

Architectural

Decorative elements, railings, street furniture, and architectural components combining aesthetics with durability.

- • Decorative castings

- • Street furniture

- • Structural elements

Why Choose Rapidaccu for Cast Iron Machining?

15 years of expertise delivering precision cast iron components to clients worldwide

Advanced Equipment

State-of-the-art CNC machines specifically configured for cast iron machining with proper dust collection and tooling.

Material Expertise

Deep understanding of various cast iron grades and their machining characteristics for optimal results.

Global Experience

Serving clients in 85+ countries with reliable international shipping and comprehensive documentation.

Machining Considerations for Cast Iron

Tooling Selection

Cast iron’s abrasive nature requires proper tool selection. We use carbide and ceramic cutting tools with appropriate geometries to achieve optimal tool life and surface finish.

Coolant Strategy

Cast iron machining typically uses dry cutting or minimal coolant to prevent thermal shock and cracking. Our processes are optimized for cast iron’s heat dissipation properties.

Dust Management

Effective dust collection systems are essential for cast iron machining. Our facilities feature advanced filtration to maintain a clean and safe working environment.

Dimensional Stability

Cast iron castings may have internal stresses. We employ stress-relieving heat treatments and proper machining sequences to ensure dimensional stability and accuracy.

Frequently Asked Questions

What cast iron machining services does Rapidaccu offer?

Which types of cast iron can you machine?

What tolerances can you achieve for cast iron parts?

What industries use cast iron machined parts?

How do you handle cast iron machining dust?

Can you machine both as-cast and heat-treated cast iron?

Request Your Cast Iron Machining Quote

Partner with Rapidaccu for expert cast iron machining services. Our experienced team is ready to deliver precision components for your applications.

Manufacturing Facility

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Contact

info@rapidaccu.comBusiness Hours

Monday – Friday: 9:00 AM – 6:00 PM (GMT+8)