- Home ›

- Plastic Machining ›

- Acrylic CNC Machining

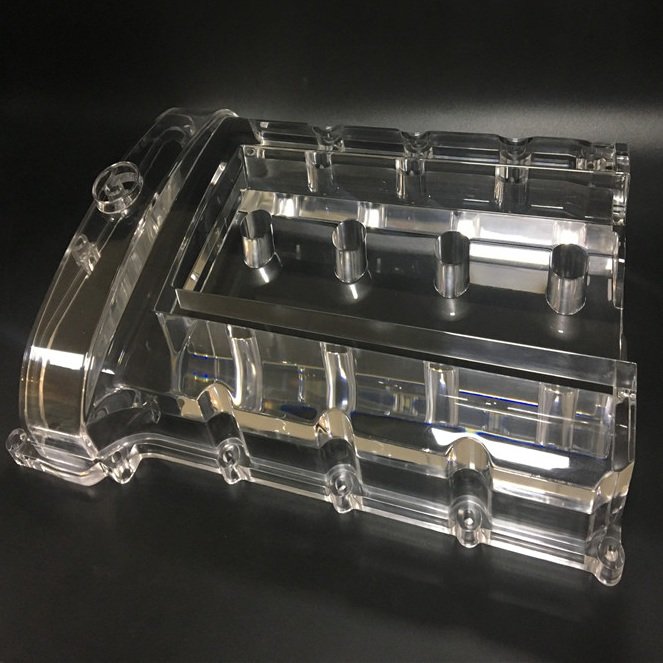

Acrylic CNC Machining Services

Premium custom acrylic parts manufacturing from China’s leading manufacturer

What is Acrylic Material?

Acrylic, also known as PMMA (Polymethyl Methacrylate) or plexiglass, is a transparent thermoplastic material known for its exceptional optical clarity, weather resistance, and versatility.

This remarkable material offers the transparency of glass with only half the weight and significantly greater impact resistance, making it an ideal choice for applications requiring both aesthetics and functionality.

With excellent UV resistance, superior surface hardness, and easy machinability, acrylic has become the material of choice across industries from signage and displays to medical devices and automotive components.

About Acrylic Machining

At Rapidaccu, we specialize in precision acrylic machining with 15 years of manufacturing excellence. Our state-of-the-art CNC equipment and skilled technicians enable us to produce custom acrylic parts with exceptional clarity, smooth edges, and tight tolerances.

We process both cast and extruded acrylic in various colors and thicknesses, offering comprehensive services including CNC milling, laser cutting, polishing, and 3D printing to meet diverse customer requirements.

Our commitment to quality and customer satisfaction has made us a trusted partner for businesses worldwide seeking premium acrylic components for their products.

Acrylic Manufacturing Solutions

CNC Machining Acrylic

Precision CNC milling and routing for custom acrylic parts with exceptional edge quality, tight tolerances, and smooth finishes. Ideal for complex geometries and high-volume production.

Discover More

Acrylic 3D Printing

Innovative additive manufacturing technology for rapid prototyping and production of complex acrylic-like parts with design flexibility and reduced lead times.

Discover More

Acrylic Injection Molding

High-volume injection molding for mass production of acrylic parts with consistent quality and cost-effective manufacturing.

Discover MoreKey Properties of Acrylic

Optical Clarity

92% light transmission

Lightweight

Half the weight of glass

Impact Resistant

10x stronger than glass

UV Resistant

Excellent weather resistance

Easy Machining

Excellent fabrication properties

Surface Hardness

Scratch resistant surface

Color Options

Wide range available

Recyclable

Environmentally friendly

Industries & Applications

Serving diverse markets with premium acrylic solutions

Retail & Display

Point-of-sale displays, product stands, sign holders, retail fixtures, exhibition displays, and promotional materials.

Architecture

Skylights, windows, partitions, decorative panels, furniture components, and lighting fixtures.

Medical Devices

Equipment housings, diagnostic device parts, incubators, safety shields, and medical instrument components.

Automotive

Instrument panels, light covers, interior trim, glazing applications, and decorative components.

Lighting

Light diffusers, LED covers, lamp shades, decorative lighting, and optical lenses.

Signage

Illuminated signs, outdoor signage, wayfinding systems, channel letters, and branding elements.

Our Acrylic Machining Capabilities

CNC Milling & Routing

Multi-axis CNC machining for complex acrylic parts with precision tolerances and smooth edge finishes.

Laser Cutting

High-precision laser cutting for intricate designs, clean edges, and minimal material waste.

3D Printing

Advanced additive manufacturing for rapid prototyping and complex acrylic-like geometries.

Polishing & Finishing

Diamond polishing, flame polishing, and various finishing techniques for crystal-clear edges.

Custom Fabrication

Bending, bonding, thermoforming, and assembly services for complete acrylic solutions.

Quality Inspection

Rigorous quality control with dimensional verification and optical clarity testing.

Why Choose Rapidaccu?

15 Years of Excellence

Proven expertise in acrylic manufacturing with thousands of satisfied customers worldwide.

State-of-the-Art Equipment

Latest CNC machines and manufacturing technology for superior quality and precision.

Competitive Export Pricing

Cost-effective manufacturing solutions without compromising on quality.

ISO Certified Quality

Rigorous quality management systems ensuring consistent excellence.

Global Shipping Network

Reliable worldwide delivery with experienced logistics partners.

Technical Support

Expert engineering team providing design assistance and manufacturing guidance.

Frequently Asked Questions

What is the difference between cast and extruded acrylic?

Can acrylic parts be used outdoors?

What tolerances can you achieve with acrylic machining?

What colors and thicknesses are available?

How do you achieve clear edges on acrylic parts?

Do you offer assembly services for acrylic parts?

Start Your Acrylic Project Today

Get professional acrylic machining services from China’s trusted manufacturer

Rapidaccu Manufacturing

Manufacturing Facility

Rongli Industrial Park, Dalang, Longhua District, Shenzhen, China

Email Contact

info@rapidaccu.comIndustry Experience

15 Years in Precision Acrylic Manufacturing

Your Trusted Partner

- ISO Quality Certified

- Global Shipping Available

- Expert Engineering Support

- Competitive Pricing

Request Your Quote

Fill out the form below and our team will contact you shortly with a detailed quote.