What is CNC Machining? The Ultimate Guide to Precision Manufacturing

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized controls and precision cutting tools to remove material from a solid block (blank) to create high-accuracy custom parts. It’s trusted for prototypes and production because it delivers exceptional repeatability, material versatility, and surface quality.

Whether you’re an engineer validating a prototype or a procurement manager scaling production, understanding CNC machining—from tolerances to DFM (Design for Manufacturability)—helps you reduce cost, shorten lead times, and ensure consistent part performance.

Featured Snippet Tip

If you only remember one thing: CNC machining is the fastest path to reliable, high-strength prototypes and production parts when you need tight tolerances, consistent quality, and real-world materials.

1) How Does CNC Machining Work? (Step-by-Step)

Unlike additive manufacturing (3D printing), CNC machining starts with a solid material blank and removes what’s not needed until the final geometry remains. A typical CNC workflow includes four stages:

Step 1 — CAD Model Design

Engineers create a 2D drawing or 3D solid model using CAD tools (e.g., SolidWorks, Fusion 360, NX, Creo).

Step 2 — CAM Toolpaths (G-code / M-code)

CAM software generates toolpaths and exports machine instructions: G-code controls motion, while M-code handles machine functions (spindle/coolant/tool change).

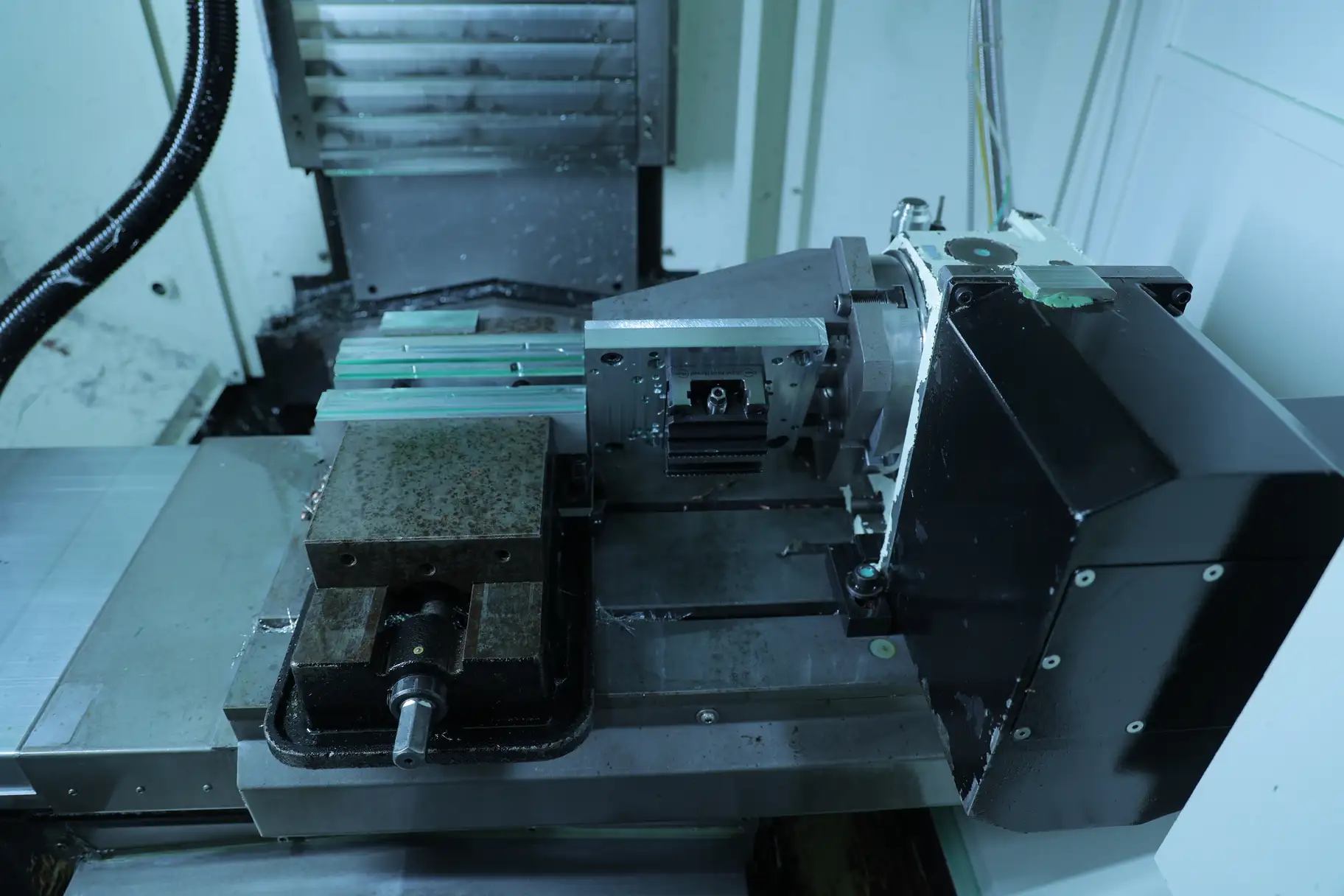

Step 3 — Machine Setup

Tools are loaded and the workpiece is secured using vices, fixtures, soft jaws, or vacuum tables. Probing ensures consistent zeroing.

Step 4 — Machining Execution

The CNC system executes the program, precisely controlling tool motion across multiple axes to achieve repeatable accuracy.

2) Common Types of CNC Machines

Choosing the right CNC machine depends on geometry, tolerance requirements, and production volume. Here’s a quick comparison:

| Machine Type | Axis | Best For | Typical Parts |

|---|---|---|---|

| CNC Milling | 3–5 | Complex shapes, pockets, prismatic geometry | Housings, brackets, enclosures |

| CNC Lathe (Turning) | 2–4 | Cylindrical parts and rotational symmetry | Shafts, pins, bushings |

| 5-Axis CNC | 5 | Complex organic shapes; fewer setups | Aerospace, medical, robotics parts |

| CNC Router | 3 | Large sheets and softer materials | Panels, plastics, aluminum plates |

Pro Insight

If your part has multiple angled faces or hard-to-reach features, 5-axis machining can reduce setups, increase accuracy, and often lowers total cycle time.

3) Core CNC Machining Operations

CNC machining is more than just “milling or turning.” Here are the most common operations used to create functional parts:

Milling

- • Facing & surfacing

- • Pocketing & slotting

- • 2D/3D contouring

- • Engraving/marking

Turning

- • OD/ID turning

- • Grooving & parting

- • Threading

- • (Optional) Knurling

Hole-Making

- • Drilling

- • Tapping

- • Reaming

- • Boring

4) High-Performance Materials for CNC Machining

One of the greatest advantages of CNC machining is its flexibility across metals and engineering plastics. Material choice impacts strength, corrosion resistance, weight, thermal performance, and cost.

Metals

- Aluminum (6061, 7075): Lightweight, excellent machinability; a CNC favorite.

- Stainless Steel (304, 316): High corrosion resistance and strength; medical & marine use.

- Titanium (Grade 5): Exceptional strength-to-weight ratio; aerospace and high-end engineering.

- Brass/Copper: Great conductivity; connectors and thermal applications.

Plastics

- POM (Delrin): Low friction & high stiffness; gears, bearings, sliding parts.

- PEEK: High-performance polymer for heat/chemical resistance; can replace metal in harsh environments.

- ABS / Polycarbonate: Great for enclosures and functional prototypes; PC offers high impact strength.

- Nylon: Tough and wear-resistant; good for low-friction components.

Material Tip

If your part faces heat, chemicals, or wear, validate the material choice against real operating conditions—don’t rely on a datasheet alone.

5) Engineering Precision: Tolerances & Surface Finishes

If you want to outrank generic content, you must address the technical requirements of professional buyers: tolerances, surface finish quality, and how both impact cost.

Typical CNC Tolerance Tiers

| Level | Range | Use Case |

|---|---|---|

| Standard CNC | ±0.125 mm (±0.005″) | General parts & housings |

| Precision CNC | ±0.025 mm (±0.001″) | Assemblies & mating fits |

| High Precision | ±0.005–0.01 mm | Bearing seats & critical features |

Pro Tip: Tight tolerances can increase cost exponentially. Apply them only to truly critical features.

Surface Finishes (Function + Appearance)

- As-Machined: Visible tool marks (Ra ~3.2μm). Most cost-effective.

- Bead Blasting: Uniform matte finish; reduces visual tooling marks.

- Anodizing (Type II/III): Protective oxide layer; Type III hardcoat for wear resistance.

- Electropolishing: Improves corrosion resistance; common for medical-grade stainless.

Finish Note

Finishing can affect dimensions slightly (e.g., anodizing/plating thickness). If your part has critical fits, plan finishing early.

6) DFM: Design for Manufacturability Checklist

DFM is where costs are won or lost. These rules help you avoid machining failures, reduce cycle time, and increase yield—especially in production.

Avoid Internal Sharp Corners

Add radii for internal corners. Smaller cutters increase time and tool wear. A practical guideline is: R ≥ 1/3 of cavity depth.

Limit Cavity Depth

Deep pockets require long tools that can vibrate (chatter), hurting finish quality. Aim for: pocket depth ≤ 4× pocket width.

Maintain Minimum Wall Thickness

Metals: ≥ 0.8mm • Plastics: ≥ 1.5mm. Thin walls can warp or deform during machining.

Use Standard Hole Sizes

Standard drill sizes reduce cost and speed up machining. Nonstandard holes may require interpolation or custom tooling.

DFM Shortcut

The fastest way to cut cost: tighten tolerance only on critical features, add radii, and reduce deep pockets. Those three changes often produce the biggest savings.

7) Cost Analysis: What Drives CNC Machining Price?

In B2B CNC machining, price isn’t just about material. A practical pricing model looks like this:

Cost Formula

Total Cost = Setup + Material + Machining Time + Post-Processing + Inspection

Setup Time (Fixed Cost)

Programming, fixtures, and first-article setup are fixed costs—this is why higher volumes reduce unit price.

Geometry Complexity

More axes, more setups, and more tight features increase machining time and inspection requirements.

Material Removal Rate

Deep pockets and heavy stock removal take longer and raise tool wear—especially in hard metals like stainless or titanium.

Finishing & Inspection

Anodizing, plating, passivation, bead blasting, and inspection reports can be major cost multipliers.

8) CNC Machining vs. 3D Printing (And When Not to Use CNC)

CNC machining and 3D printing solve different problems. Here’s a practical comparison:

| Feature | CNC Machining | 3D Printing (FDM/SLS) |

|---|---|---|

| Material Strength | Isotropic (strong in all directions) | Anisotropic (weaker between layers) |

| Precision | Very high (micron-level capable) | Moderate |

| Lead Time | 5–10 days typical | 1–3 days typical |

| Economy of Scale | High (unit cost drops with volume) | Lower (unit cost stays flatter) |

When CNC is NOT the Best Choice

- • High-volume plastic parts → Injection molding

- • Thin sheet-like parts → Sheet metal fabrication

- • Complex internal channels → Additive manufacturing

- • Extremely large parts → Casting + machining or modular design

9) Real-World Applications of CNC Machining

CNC machining supports industries that demand precision, quality, and reliability—especially where performance cannot be compromised.

Aerospace

Turbine components, structural brackets, and high-strength assemblies—often in titanium and aerospace-grade aluminum.

Medical

Surgical instruments, device housings, and precision components requiring strict inspection and clean finishes.

Automotive

Engine and transmission-related components, fixtures, and prototypes requiring repeatable quality.

Electronics & Robotics

Heat sinks, enclosures, connector parts, and precision mounts that must assemble cleanly and consistently.

10) Quality Control: What to Ask Your CNC Supplier

A CNC quote means little without quality clarity. Reliable production depends on inspection capability, documentation, and revision control.

Inspection & Reporting

- • First Article Inspection (FAI)

- • CMM inspection for critical features

- • Dimensional report on request

Traceability & Process Control

- • Material certificates (upon request)

- • Batch consistency planning

- • Revision control for drawing updates

High-Impact Buyer Questions

- • Do you provide FAI or CMM reports for critical dimensions?

- • How do you handle design revisions and version changes?

- • Can you recommend DFM changes to reduce cost without hurting function?

- • What’s your standard yield plan for production runs?

11) Quote Checklist: Get Accurate Pricing Faster

To get an accurate CNC machining quote quickly, send the right inputs. This reduces back-and-forth and ensures your price matches reality.

Files & Drawings

- • 3D file: STEP / IGES / X_T

- • 2D drawing: tolerances, GD&T, critical features

- • Notes for surface finish and marking

Production Requirements

- • Quantity: prototype / low volume / production

- • Material spec: e.g., Al 6061-T6, SS316, PEEK

- • Finish: anodize, plating, passivation, bead blast

Inspection

- • Standard inspection or report required?

- • CMM for critical dimensions?

- • First Article Inspection (FAI)?

Lead Time & Packaging

- • Standard vs expedited delivery

- • Special packaging: scratch/clean handling

- • Shipping & labeling requirements

Ready to move from design to production?

Request a CNC Quote + Free DFM Review

Upload your files and requirements. Our engineers will highlight cost-saving DFM improvements before production starts.

12) FAQs about CNC Machining

These are the most common questions engineers and procurement teams ask before placing a CNC machining order.

Is CNC machining expensive for one-off prototypes?

What tolerance can CNC machining achieve?

What is the minimum wall thickness for CNC machining?

Can CNC machining work with hardened steel?

Do anodizing or plating processes affect final dimensions?

What should I include to get a fast and accurate CNC quote?

Next step: If you want this Pillar Page to rank faster, publish 6–10 supporting “cluster articles” (tolerances, finishes, materials, 5-axis, CNC cost, DFM guide) and link them internally from this page.